Reviews Are In

From Toys to End - Use Parts For Families.

From Prototype to Functional Parts

From Industrial to Personal

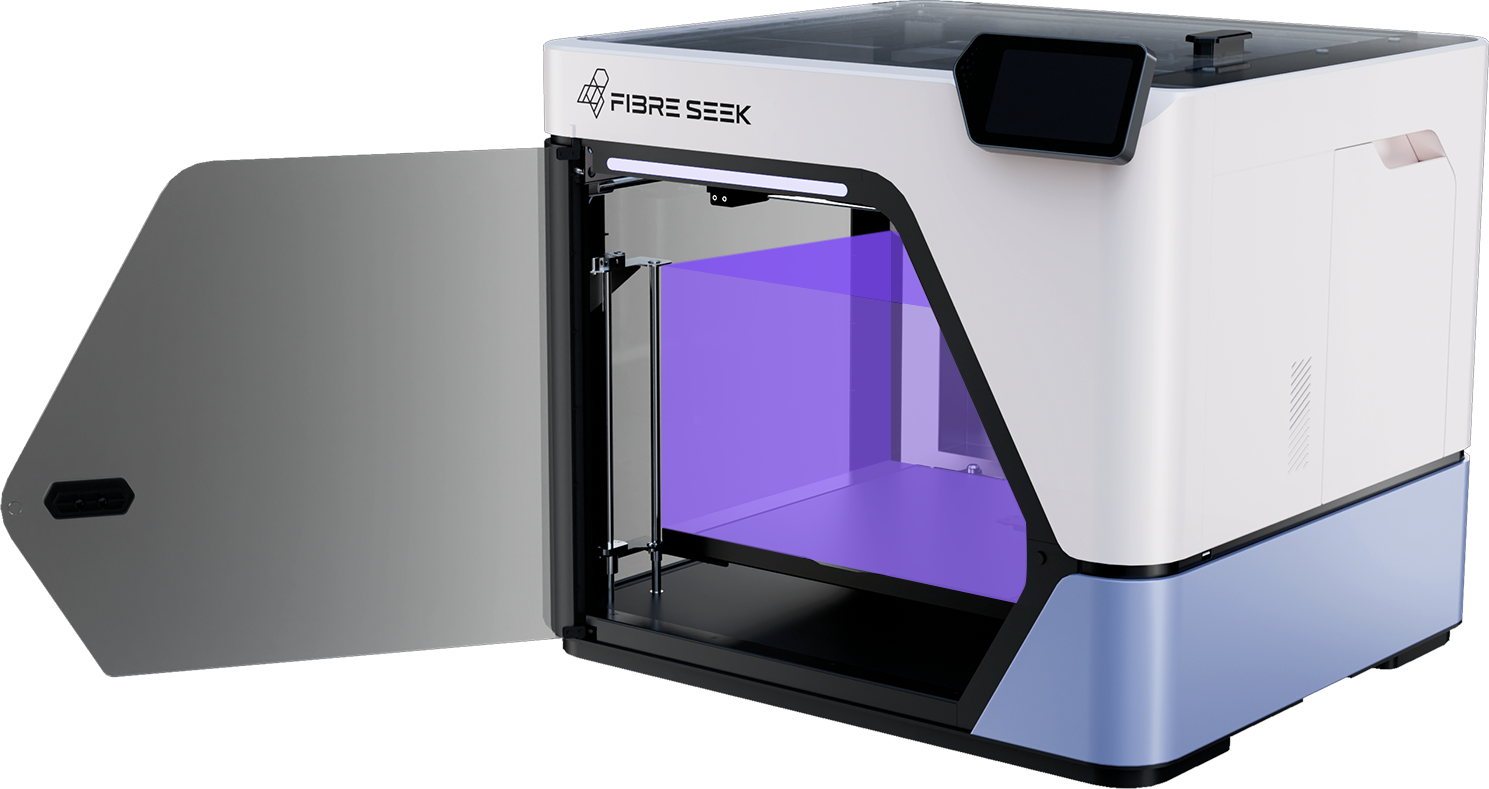

Bring CFC Printing Home

FibreSeeker Real Continuous Carbon Fibre

Cost-Effective Continuous Carbon Fibre

2 Times the Strength of Aluminum,

1/2 of the Weight

FibreSeeker 3 Game-Changing Tensile Strength

Upgraded Tensile Strength Performance

Print Ultra-Strong Parts with Carbon/Glass Fibres – up to 900MPa Tensile Strength

Move Faster. Print Bigger.

Large Build Volume – 300 x 300 x 245mm

Next-Gen 3D Printing for Makers & Pros

Endorsed By

As See In

The Magic of CFC Technology ,

How It Works

Dual-Nozzle 3D Printing

—— CFC +FFF

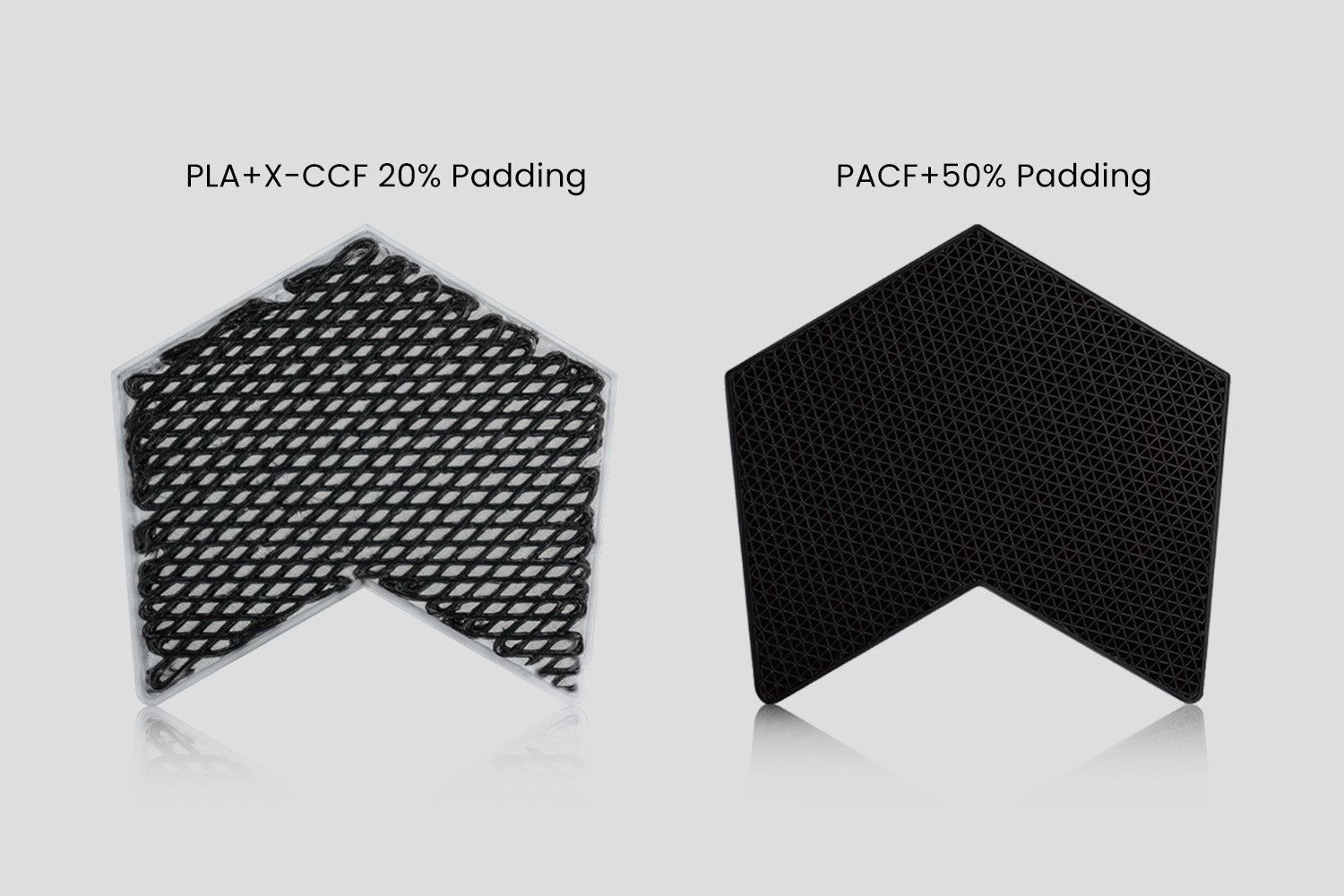

The Optimal Structure of Composites

Composite Lattice Infill VS Normal FFF Printouts

One Machine. Three Modes. Infinite Possibilities

Wide Selection of Materials

Aura Slicer Suite: Zero-Click Precision

Smart & Easy to Use

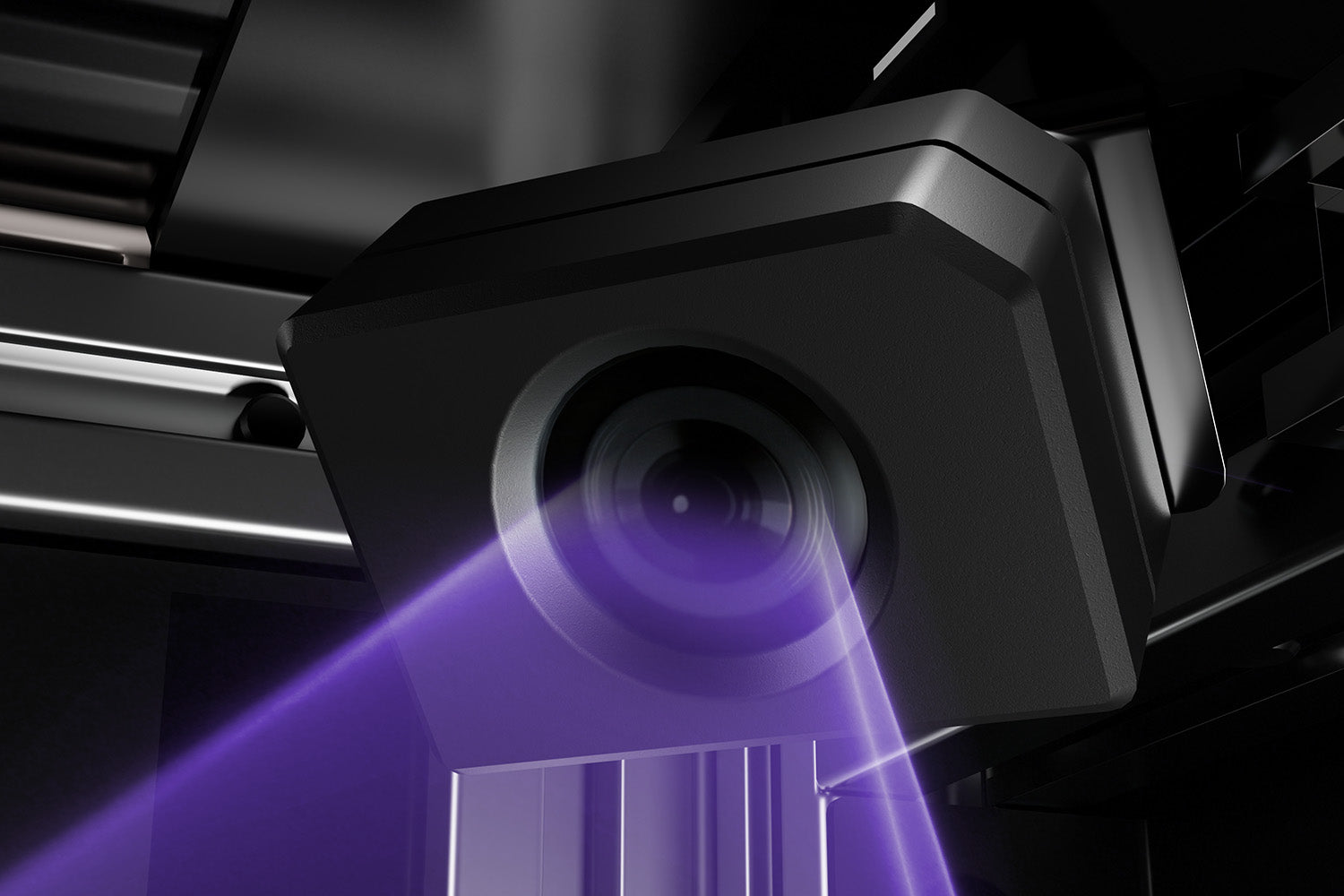

AI Camera Monitoring

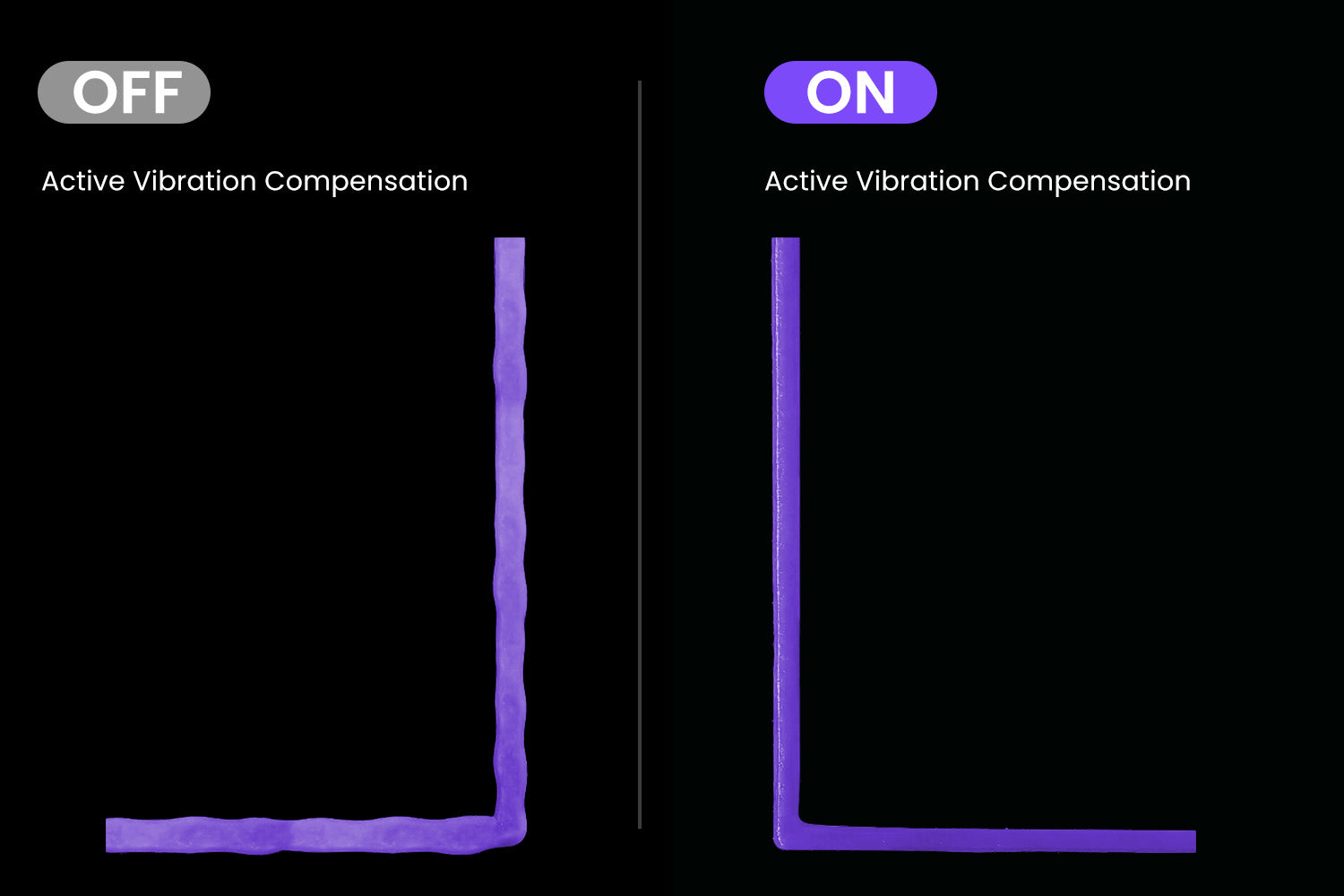

Active Vibration Compensation

So Strong, So Light.

Check Out FibreSeeker 3 in Action

How We Stand Out?

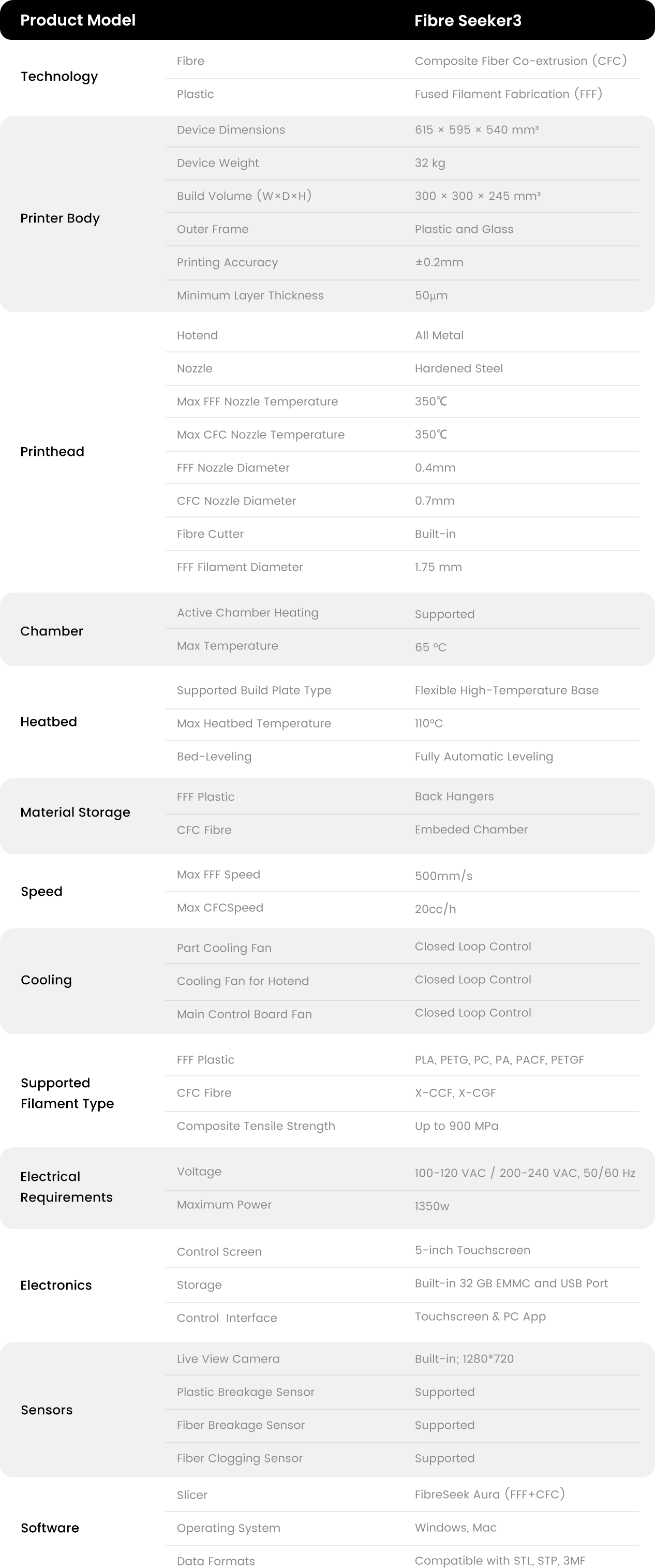

Specifications